Overvoltage protection is critical to the long-term health of any cable. DC overvoltage testing (also known as withstand testing) is the most popular method of general condition and integrity assessment in the power, industrial and domestic markets. This method of testing is distinguished a number of key advantages:

Transient overvoltage on the supply, which is typically a very brief voltage spike, can be easily simulated and tested by DC withstand test equipment. DC withstand testing equipment is generally smaller and lighter than an equivalent AC test set. Because overvoltage tests are typically field based, being able to easily transport your tester is critical. Another significant advantage is that DC overvoltage testing has been a popular method for a long time, so there is plenty of historical data available from different technical bodies. Reference to these records allows operators to monitor condition quality through trend analysis. By regularly updating this data, insulation quality and integrity can be monitored indefinitely.

However, DC overvoltage testing is not always a perfect simulation of the stresses that power systems contend with on a day-to-day basis. For example, many power systems are subjected to frequencies of 50/60 hertz in their operational state, which are not always accurately represented. For conditions such as these, an AC test set is recommended.

220000 series - 70/120/160 K V DC DIELECTRIC TEST SETS

- Lightest weight available in air-insulated high-voltage model

- Advanced performance with long-term reliability provided by filtered half-wave rectification

- Designed for maximum operator safety

High Voltage DC dielectric test sets provide the most dependable, portable DC highvoltage sources for checking the quality of electrical power cables, motors, switchgear, insulators, transformers and capacitors.

*Please note the analog models are no longer available.

EST - HIGH VOLTAGE DISCHARGE ROD

- Choice of 6 versions of discharge rod

- Complies with EN 50191, EN 61230 and EN 61219

- Versions for 35 kV to 150 kV working.

- Discharge resistors ensure damped discharge

For damped discharge and direct, visible earthing.

In its tip with which the live conductor is touched the SebaKMT discharge rod features a discharge resistor which limits the discharge current and ensures a damped discharge.

Within a split second, most of the charge of the cable has flown off a post charging effect is thus eliminated.

The discharge rods are made of GFK (fibre glass strengthened plastic). They are equipped with a handle and conservatively rated clearance against physical contact with high voltage.

HPG70-K - 70 KV DC PORTABLE HV TEST SYSTEM

- Highest safety thanks to fully insulated design

- Separate control and HV-unit

- Voltage continuously adjustable

- Expandable with a VLF CR attachment for VLF testing on MV cables

HV test set 50 kV, HV test set 80 kV and HV test set 110 kV - PORTABLE HIGH VOLTAGE TEST SET FOR D.C. TESTING OF CABLE

- Highest safety by monitoring functions and easy operation

- Quick and easy mounting with compact and simple setup

- Meeting individual needs by modular design

The HV Test Set is a cable tester for DC voltage testing of cables and cable installations in accordance with the international standards. It consists of an operation unit and HV unit. Due to its small size and low weight the test sets can easily be transported and used on-site. The HV Test Set is available in three versions (50/80/110 kV DC).

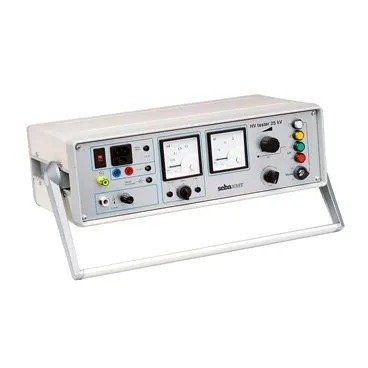

HV Tester 25 - HIGH VOLTAGE GENERATOR

- DC and insulation testing of cables, joints, electrical fixtures, etc.

- High flexibility with built-in battery

- Internal discharge facility

T 99/1 - HIGH POTENTIAL TESTER (HIPOT)

- Ideal for field application because of its low weight and compact design

- High safety due to internal discharge facility

- High flexibility with the external battery

- Over-current tripping

The high voltage test unit T99/1 is a portable and powerful test device able to generate a DC voltage of up to 40 kV. The T 99/1 is used for testing of cables, cable accessories, plant and installations. Because of the short-circuit proof design and high output current of the T 99/1, this is device is also suitable for cable fault location (in conjunction with a TDR unit).

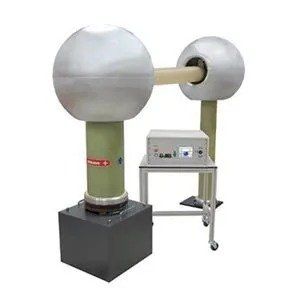

T26/1A 200 kV, T26/1B 400 kV and T26/1C 800 kV - HIGH VOLTAGE TEST SETS

- Great mobility

- Simple, safe operation

- Thermal overload shutdown

- Discharge switch

The sets are primarily designed for power supply companies, cable laying firms and cable manufacturers for the DC voltage testing of high-voltage systems and cables. Their short-circuit-proof output circuit and high power make them suitable for use in fault location as a burn-down unit for burning high-impedance and intermittent cable fault.