ALL-TEST PRO 34™

- Patented Technology

Patented Dynamic Stator and Rotor Signatures™

Used to evaluate the condition of the stator and squirrel-cage rotor in a single test. Perfect for testing new and repaired motors prior to acceptance.

Patented Test Value Static™ (TVS™)

Test Value Static (TVS) is a sum calculated from the 3-phase MCA static test and is used as a reference value for the motor. Common types of faults in the rotor and stator windings will change TVS.

- Obtain Return On Investment

Finding just one fault using the AT34™ can save your organization countless hours of downtime and provide thousands of dollars in savings. Maximize your investment by:

- Testing newly installed motors to ensure proper installation and prevent startup failure.

- Testing motor spares to ensure they are in good condition and ready for service.

- Troubleshooting motors that have quit running by testing from the MCC or directly at the motor.

- Implementing it into a PdM testing program to detect developing faults before they cause catastrophic motor system failures.

Finding a motor fault before it breaks can save you countless hours of downtime and can provide thousands of dollars in savings.

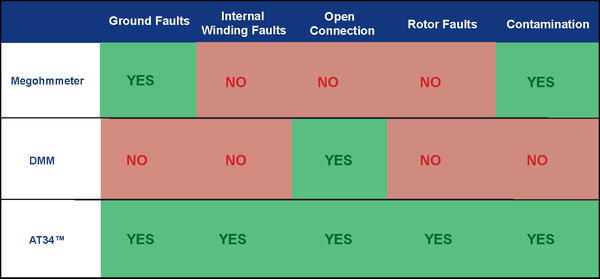

- Test Capabilities

Tests AC induction, squirrel-cage rotor motors <1000V. The electrical health of all motor components is evaluated, including induction windings and rotor, associated connections and cables.

- Motor Component Health Assessment

The electrical health of all motor components is evaluated, including, but not limited to:

- Induction windings

- Rotor

- All associated connections and cables

- ALL-TEST PRO 34™ Features

- On-screen step-by-step testing instructions

- Tests take less than 3 minutes

- Tests can be performed from over 1000′ away

- Detects faults at the earliest stages before motor failure

- A timing tone that supports proper rotation speed during deenergized dynamic test

- Boot loader function facilitates firmware updates at the customer’s site

*Note: Route feature will only work with Enterprise Software.

TRITAN ENGINEERING SDN. BHD.

No. 28, Jalan Permas 9/13,

Bandar Baru Permas Jaya,

81750 Masai, Johor, Malaysia

Tel: +607-388 2010

Fax: +607-388 4316

Email: koh1@tritan.com.my

ABOUT TRITAN

Tritan Engineering Sdn. Bhd. is an instrumentation trading company, specialized in supplying testing equipment designed for both electrical and mechanical applications. We carry products from Pruftechnik, Druck, All Test Pro, Megger, Chauvin Arnoux, AVIO, RF System, SDT, Micronics, Hilger Kern, SIUI, Vaetrix and PMDT.

All Rights Reserved | Tritan Engineering Sdn. Bhd.